Product production steps

IOC

Ball-milling ---Prilling

Dry Pressing

High sintering

Processing

Inspection

Advantages

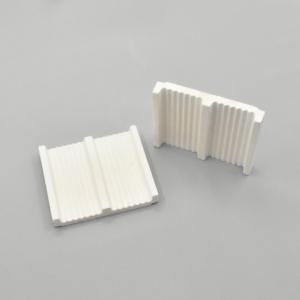

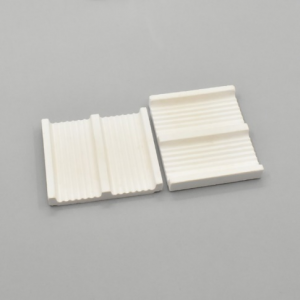

Our push plate and crucible have high content of alumina, working temperature of 1800 ℃, excellent high temperature resistance, thermal shock resistance and deformation resistance, long life, fine surface, good bonding strength, not easy to fall off, good high temperature strength and not easy to deform. It has been widely used in various electric furnaces and high temperature sintering furnaces.

Application Introduction

Widely used in ceramics, electronics, magnetic materials, rare earth, fluorescent materials, glass, metallurgy and other industries in the tunnel push plate kiln, shuttle kiln, electric furnace, and other high temperature parts.

Tech specs

| Model No. | Push plate | Model No. | Crucible |

| Volume density: | 3.6g/cm^3 | Volume density: | 3.6g/cm^3 |

| Apparent porosity: | 19.3% | Apparent porosity: | 19.3% |

| Compressive strength: | ≥85MPa | Compressive strength: | ≥85MPa |

| Maximum operating temperature: | 1800℃ | Maximum operating temperature: | 1800℃ |

| Long-term operating temperature: | 1750℃ | Long-term operating temperature: | 1750℃ |

| Reheating linear-change: | ≤0.1 | Reheating linear-change: | ≤0.1 |

| Main material: | AL2O3 | Main material: | AL2O3 |

Note: As products are constantly updated, please contact us for latest specifications.