Category

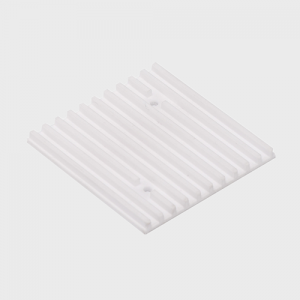

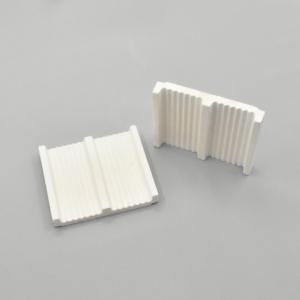

A ceramic heat sink is a device that dissipates heat from the heat-prone electronic components of an electrical appliance. At present, the commonly used alumina ceramic sheet, aluminum nitride ceramic sheet, silicon carbide ceramic sheet.

Alumina ceramic sheet: It has high thermal efficiency, thermal conductivity: 24W/M.K, high temperature/high pressure resistance, heat evenly, fast heat dissipation. In addition, it has simple and compact structure, small size, smooth surface, high strength and it is not easy to break, acid and alkali corrosion resistance, durable.

Aluminum nitride ceramic sheet:The color is gray white, smooth surface, can be customized into any shape or size, easy to use and install. This ceramic radiator has a very high thermal conductivity, the thermal conductivity is 7-10 times of alumina ceramic sheet, can reach 180W high, its electrical insulation performance is very stable, dielectric constant and medium loss is low, can withstand 1800 degrees Celsius and does not affect the performance of the product. With the rapid development of electronic equipment, the demand for electronic or auxiliary products is also increasing, and the application rate of this product as a high thermal conductivity aluminum nitride ceramic sheet as a matrix or packaging material is becoming more and more extensive in the market.

Silicon carbide ceramic sheet: It is green environmental protection materials, it belongs to the microporous structure, in the same unit area can be more than 30% porosity, greatly increase the heat dissipation area and air contact, enhance the heat dissipation effect. At the same time, its heat capacity is small, its own heat storage is small, the heat can be transferred to the outside world more quickly, the main characteristics of ceramic heat sink: environmental protection, insulation and high pressure resistance, efficient heat dissipation, to avoid the breeding of EMI problems. It can effectively solve the problems of heat conduction and heat dissipation in the electronics and home appliances industry. At the same time, it is especially suitable for small and medium wattage power consumption. The design space pays attention to the light, thin, short and small products, which can provide technical support and application for the innovation and development of electronic products.

Advantages

1.Ceramic heat sink can directly heat dissipation, and the speed is very fast, reducing the influence of insulation layer on thermal efficiency;

2.Ceramic heat sink is a polycrystalline structure, this structure can strengthen the heat dissipation, beyond the market most thermal insulation materials;

3.Ceramic heat sink can be multi-directional heat dissipation, speed up heat dissipation;

4.Ceramic heat sink’s insulation, high thermal conductivity, high voltage resistance, high temperature resistance, wear resistance, high strength, oxidation resistance, acid and alkali resistance, long service life, low thermal expansion coefficient can ensure the stability of ceramic heat sink in high and low temperature environment or other harsh environment;

5.Ceramic heat sink can effectively anti-interference (EMI), anti-static;

6.Ceramic heat sink using natural organic materials, meet the requirements of environmental protection;

7.Ceramic heat sink’s small volume, light weight, high strength, can save space, save materials, save freight, more conducive to the reasonable layout of product design;

8.Ceramic heat sink can withstand high current, high voltage, can prevent leakage breakdown, no noise, will not produce coupling parasitic capacitance with MOS and other power tube, and therefore simplify the filtering process, it requires the creepage distance is shorter than the metal body requirements, can further save the board space, more conducive to the design of engineers and electrical certification.

Application Introduction

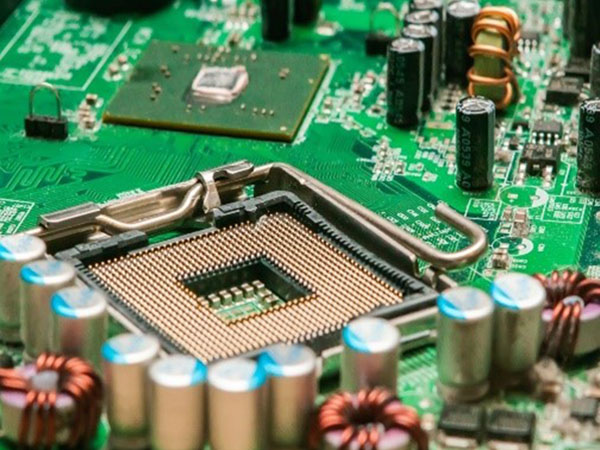

Ceramic heat sink is mainly used in the product parts that need heat conduction insulation, such as high-power equipment, IC MOS tube, IGBT patch type heat conduction insulation, high-frequency power supply, communication, mechanical equipment. In addition, ceramic radiator will also be used in LED lighting, high frequency welder, power amplifier/sound, power transistor, power module, chip IC, inverter, network/broadband, UPS power supply and so on.

Electronics Industry

Lighting Industry

Textile industry