Introduction

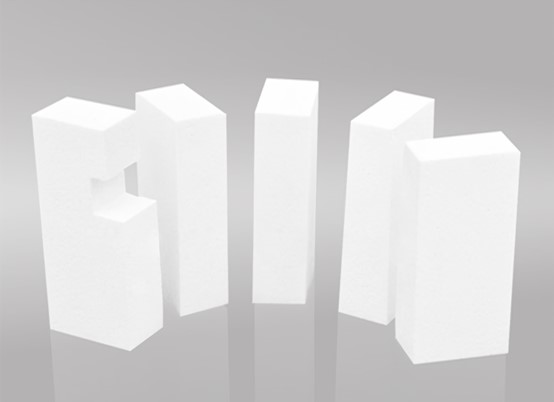

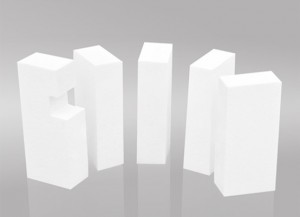

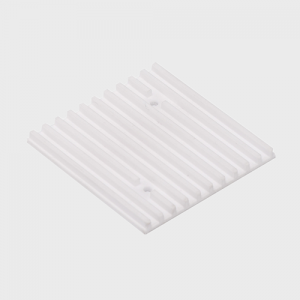

Alumina hollow bulb brick / Alumina bubble brick is made of alumina hollow ball as the main raw material, corundum ultrafine powder as additive, organic material as binder, after forming and drying process, and finally fired in 1750℃ high temperature kiln. It belongs to the category of light corundum insulation brick, this material has both low thermal conductivity of insulation brick, and high compressive strength, It is a light thermal insulation brick that can be used normally at 1700℃. Alumina hollow ball brick/ Alumina bubble brick has excellent high temperature resistance and heat insulation performance, can be directly used as the working lining of high temperature furnace, for reducing the weight of furnace body, reforming the structure, saving materials, saving energy, will achieve obvious results.

Process

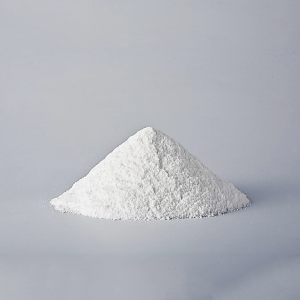

The production process of alumina hollow ball is roughly as follows: First of all, the raw material of alumina is added into the dumping type arc furnace to melt into liquid, and then the furnace is dumped at a certain angle, so that the molten liquid flows out of the pouring tank at a certain speed, and the liquid flow through the flat nozzle of 60°~90 with the pressure of 0.6~ 0.8mpa high speed airflow will blow away the liquid flow, that is, alumina hollow ball. The alumina hollow balls are usually divided into five sizes after screening and the broken balls are removed by liquid separation.

Advantage

1. High temperature: High softening temperature under load. Reburning wire change rate is small, longer use.

2. Optimize the structure, reduce the weight of furnace body: Now the kiln lining using high temperature resistant materials are heavy brick, volume density of 2.3-3.0g/cm, and alumina hollow ball brick only 1.3-1.5g /cm, the same cubic meter volume, using alumina hollow ball brick can reduce 1.1-1.9 tons of weight.

3. Save materials: To achieve the same use temperature, such as the use of heavy corundum brick price and alumina hollow ball brick price is similar, but also need considerable insulation layer refractory material. If the use of alumina hollow ball brick, per cubic meter can save 1.1-1.9 tons of heavy corundum brick usage, more can save 80% of fire insulation materials.

4. Energy saving: Alumina hollow ball has obvious thermal insulation characteristics, low thermal conductivity, can play a good thermal insulation effect, reduce heat emission, improve thermal efficiency, so as to save energy. The energy saving effect can reach more than 30%.