Low MOQ for Casting Machine Part - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

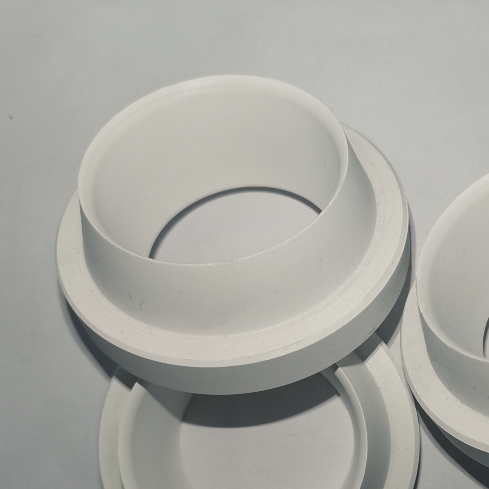

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Low MOQ for Casting Machine Part - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Bandung, Liverpool, UAE, Selling our products causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

-

Wholesale Discount Ceramics Crucible - Ceramic...

-

Hot New Products E-cigarette liquids atomizer -...

-

High Quality Wear-resistant Rubber - Ceramic p...

-

OEM Supply Mullite Castable Refractory - Ceram...

-

New Delivery for Ceramic Heating Rod - Aluminu...

-

Factory For Ceramic Square Pipe - Ceramic Wate...