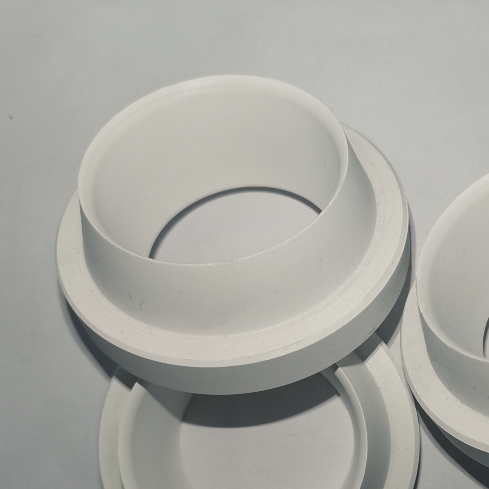

Well-designed Thermal Shock Stability - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Well-designed Thermal Shock Stability - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Malaysia, Oslo, The Swiss, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

-

High Quality for 9mm Zirconia Ball - Self-lubr...

-

professional factory for Refractory Ceramic Rin...

-

Quality Inspection for Earth Magnetic - Cerami...

-

Discountable price Wear Resistant Steel - Cera...

-

100% Original High Temperature Insulation - Ce...

-

Cheap PriceList for Ceramic Sleeve - Self-lubr...