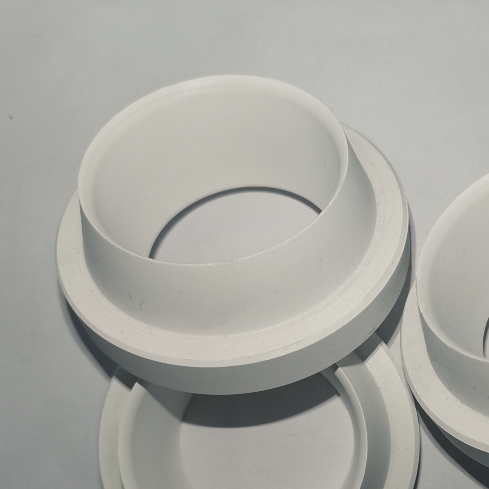

China Manufacturer for Sic Ceramic Industry - Ceramic aluminum titanate sprue sleeve bushing – SEM Detail:

Product production steps

Advantages

Lower coefficient of thermal expansion

Excellent thermal shock resistance

No infiltration with molten aluminum and other non-ferrous metal molten

Application Introduction

In the equipment used in the production of cast aluminum alloy wheels, aluminum rod casting, slab casting, and aluminum alloy casting, it is necessary to use ceramic sprue sleeve bushing to form part of the low-pressure runner.

In the casting process, traditional metal sprue bushings have disadvantages such as inability to resist corrosion, fast heat conduction, difficulty in adjusting the casting process and large fluctuations, and are greatly affected by the environment and the temperature of the raw materials. Ceramic aluminum titanate sprue sleeve bushing has the advantages of corrosion resistance, strong heat preservation, high temperature resistance, etc., which effectively guarantees the temperature of the feeding channel, the production efficiency is significantly improved, and the quality of castings is significantly improved. The weight of waste solidified in the riser is only half of that of traditional metal materials.

Tech specs

| Size and form: | OD 30~100mm |

| Main components: | Composite aluminum titanate |

| Bending strength: | 85MPa |

| Compressive strength | 160GPa |

| Low temperature bending | ≤5% |

Material & Application

Product detail pictures:

Related Product Guide:

Sticking to the perception of "Creating products of top of the range and earning mates with people today from all over the world", we constantly put the desire of consumers in the first place for China Manufacturer for Sic Ceramic Industry - Ceramic aluminum titanate sprue sleeve bushing – SEM, The product will supply to all over the world, such as: Nepal, Argentina, Guyana, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

-

High reputation Steel Ball Rollers - Self-lubr...

-

Discount Price Refractory Mullite Ceramic Disc ...

-

Wholesale Discount Granulator Granulating Machi...

-

Discount Price Construction Industry - Ceramic...

-

Factory supplied Magnetic Magnet - Ceramic Wat...

-

Manufactur standard Atomizing Sterilizing Machi...