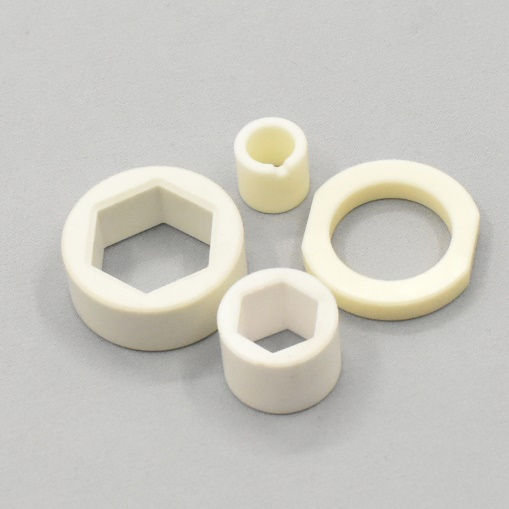

China Manufacturer for rotor shaft in ac generator - Aluminum oxide Ceramic shaft / Shaft seal – SEM Detail:

Product production steps

Advantages

Excellent wear resistance, equivalent to 266 times of manganese steel.

High hardness. Far more than stainless steel in wear resistance.

Light weight, its density is 3.9g/cm3, can reduce equipment load.

The material itself is resistant to the high temperatures of 1600℃ and has good self-lubrication. There is no expansion caused by temperature difference between 100℃ and 800℃.

The material itself has the characteristics of corrosion resistance and can be used in the fields of strong acid, strong base, inorganic, organic salt, seawater, etc.

No magnetic, no dust absorption, low noise; Can be used in demagnetization equipment, precision instruments and other fields.

Application Introduction

High speed digital motor and ordinary high-speed motor.

All kinds of brushless motor pumps.

All kinds of motors with high resistance of temperature, acid, and alkali environment.

Sample case

Most cordless vacuum cleaners use a traditional brushless DC motor, which typically runs at 25,000 times /Min.

Digital motor using ceramic shaft as rotating shaft. Although small, but powerful, using digital pulse technology, generate electromagnetic force, drive magnetic force rotation, the speed of up to 125000 times /Min.

Tech specs

| Model No. | Ceramic shaft / Shaft seal |

| Main components: | Al2O3 made in Japan |

| Hardness: | ≥HV0.5N1650 |

| Bending strength: | 400Mpa |

| Compressive strength: | 3500Gpa |

| Operating temperature: | 1000℃ |

| Size: | OD 1-50mm |

Note: As products are constantly updated, please contact us for latest specifications.

Applicable Industry

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for China Manufacturer for rotor shaft in ac generator - Aluminum oxide Ceramic shaft / Shaft seal – SEM, The product will supply to all over the world, such as: Mongolia, Pakistan, Ethiopia, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

-

Ordinary Discount Organic Chemicals - Self-lub...

-

Professional Design High Thermal Conductivity C...

-

Factory source Textile Ceramic Pipe - Self-lub...

-

Factory Promotional Industrial Magnet - Cerami...

-

Hot Selling for Nasal Atomizing - Porous ceram...

-

Low price for Cartridge Valve Faucet - Ceramic...