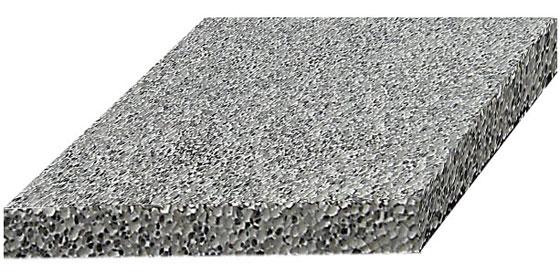

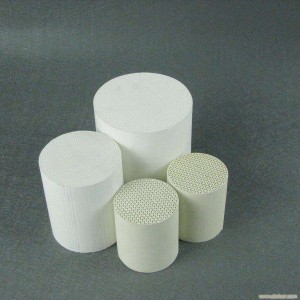

Porous ceramic is an inorganic non-metallic powder sintered body containing a certain amount of voids. The fundamental difference from other inorganic non-metallic (dense ceramics) is whether it contains voids (pores) and what volume percentage of voids (pores) it contains. According to the pore-forming method and voids, porous ceramics can be divided into: foamed ceramics, honeycomb ceramics, and granular ceramics.

Due to the existence of a certain amount of pores, the structure, properties and functions of porous ceramics have been significantly changed. Compared with dense ceramics, porous ceramics have the following five characteristics:

1. Small bulk density and light weight.

2. Large specific surface area and good filtering function.

3. Low thermal conductivity, good thermal and sound insulation properties.

4. Good chemical and physical stability, can adapt to various corrosive environments, has good mechanical strength and stiffness, and good heat resistance.

5. The process is simple and the cost is low.

1. Applied to filtration and separation devices

The filter device composed of plate-shaped or tubular products of porous ceramics has the characteristics of large filtering area and high filtering efficiency. It is widely used in the purification of water, the separation and filtration of oil, and the separation of organic solutions, acid-base solutions, other viscous liquids and compressed air, coke oven gas, steam, methane, acetylene and other gases. Because porous ceramics have the advantages of high temperature resistance, wear resistance, chemical corrosion resistance, and high mechanical strength, they are increasingly showing their unique advantages in the application fields of corrosive fluids, high temperature fluids, and molten metals.

2. Applied to sound absorption and noise reduction device

As a sound-absorbing material, porous ceramics mainly use its diffusion function, that is, to disperse the air pressure caused by sound waves through the porous structure to achieve the purpose of sound absorption. Porous ceramics as sound-absorbing materials require small pore size (20-150 μm), high porosity (above 60%) and high mechanical strength. Porous ceramics have now been used in high-rise buildings, tunnels, subways and other places with extremely high fire protection requirements, as well as in places with high sound insulation requirements such as TV transmission centers and cinemas.

3. Applied to industrial catalyst carrier

Since porous ceramics have good adsorption capacity and activity, after being covered with catalyst, the conversion efficiency and reaction rate will be greatly improved after the reaction fluid passes through the pores of the porous ceramics. At present, the research focus of porous ceramics as catalyst supports is the inorganic separation catalytic membrane, which combines the separation and catalytic properties of porous ceramic materials, and thus has a wide range of application prospects.

4. Applied to sensitive electronic components

The working principle of the humidity sensor and gas sensor element of the ceramic sensor is that when the microporous ceramic is placed in a gas or liquid medium, some components in the medium are adsorbed or reacted by the porous body, and the potential or current of the microporous ceramic is at this time. changes to detect the composition of the gas or liquid. Ceramic sensors have the characteristics of high temperature resistance, corrosion resistance, simple manufacturing process, sensitive and accurate testing, etc., and can be suitable for many special occasions.

Post time: Aug-11-2022